Laser sensors for displacement, distance and position

Micro-Epsilon Optronic develops and produces laser-optical displacement sensors.

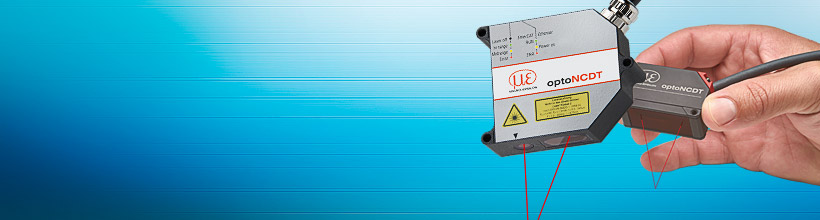

Laser-based optical displacement sensors measure a target from large distance using a very small spot which enables measurements on smallest parts. The large measurement distance enables measurements to be taken on difficult target surfaces such as hot metals. The non-contact principle enables wear-free measurements as the sensors don't have any physical contact with the target. Furthermore, the laser triangulation principle is ideal for very fast measurements with high accuracy and resolution.

These laser sensors are used in measurement and monitoring tasks in factory automation, electronics production, robotics and vehicle construction.

Laser triangulation principle

Laser triangulation sensors use a laser diode that projects a visible light point onto the targets surface. The reflected light is directed through an optical receiving system onto a position-sensitive element. If the light point changes its position, the change will be analyzed in the receiver element. CMOS elements are being used as position-sensitive measuring elements.